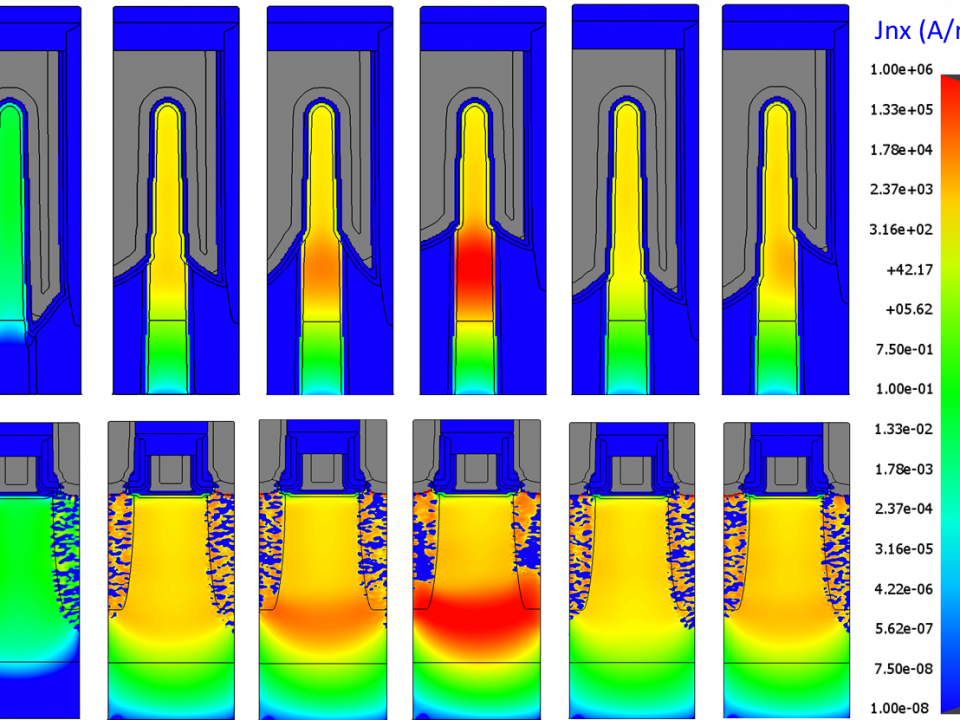

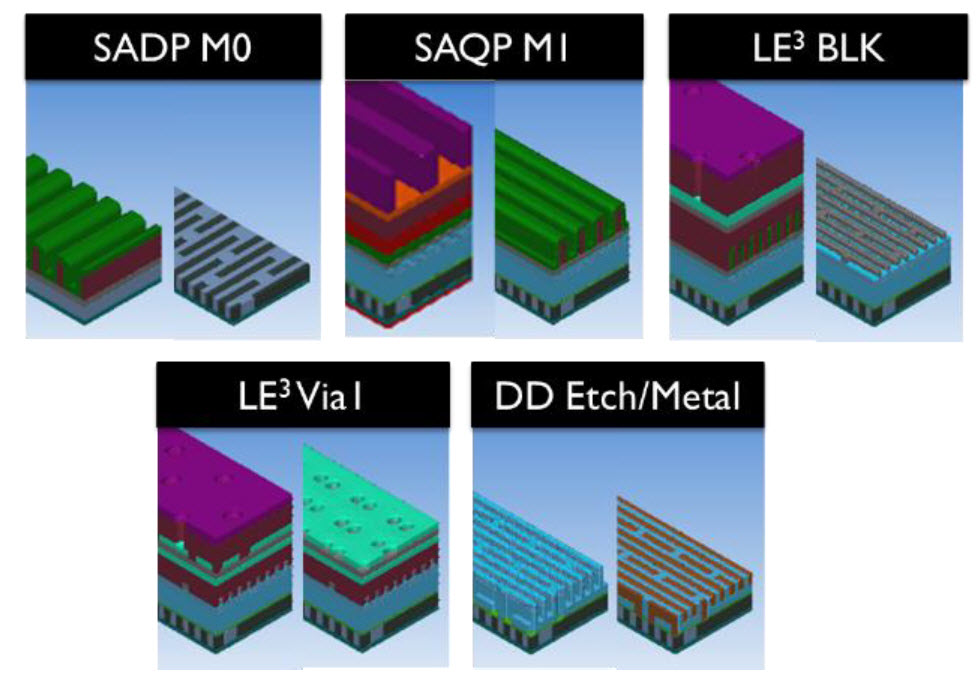

A million wafer, virtual fabrication approach to determine process capability requirements for an industry-standard N5 BEOL two-level metal flow

December 1, 2016

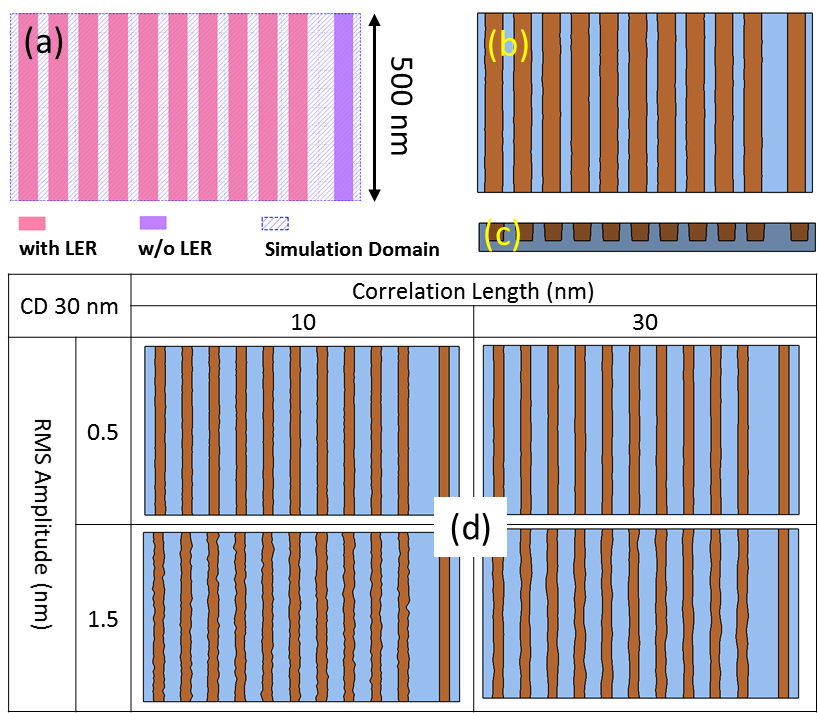

Optimizing DRAM Development using Directed Self-Assembly (DSA)

February 13, 2017You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. If you do not have an account, we invite you to request an account.

Whitepaper: New Techniques to Analyze and Reduce Etch Variation

To download your free white paper, please fill out the form below:

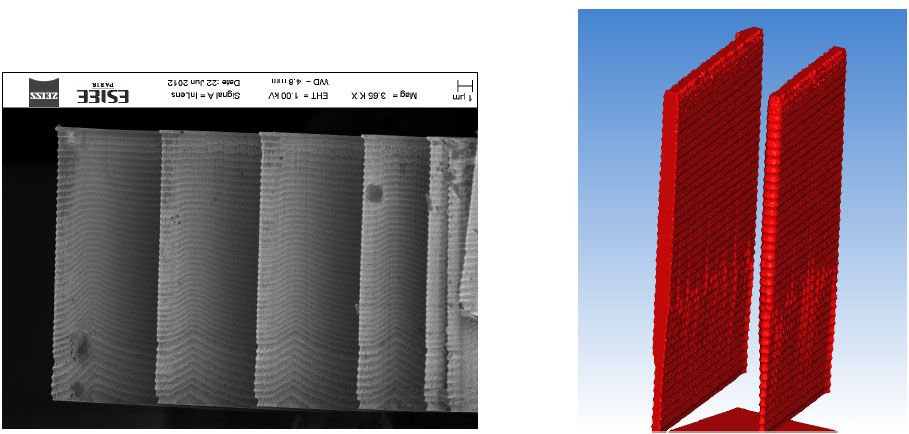

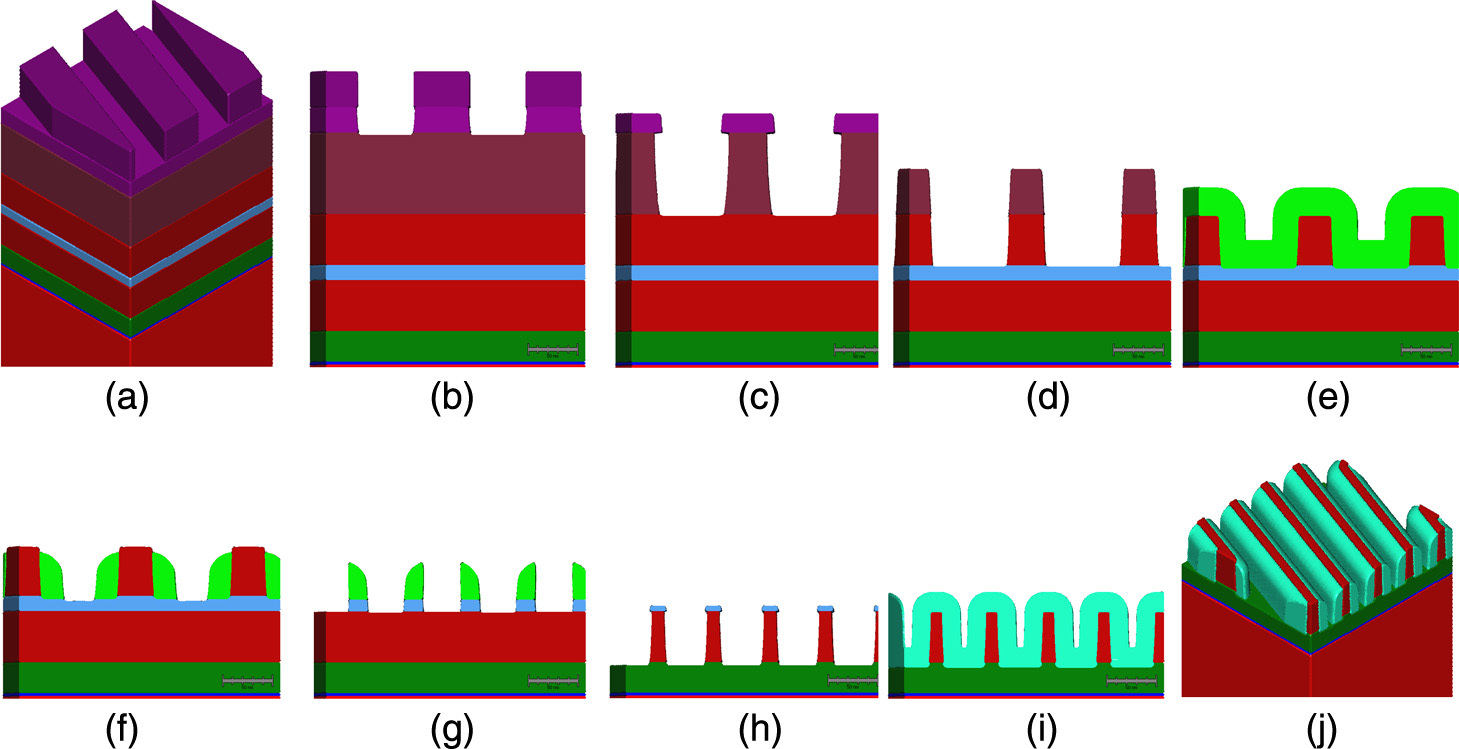

Time division multiplex (TDM) plasma etch processes (commonly referred to as Deep Reactive ION Etching (“DRIE”)) use alternating deposition and etch steps cyclically to produce high aspect ratio structures on a silicon substrate. These etch processes have been widely applied in the manufacturing of silicon MEMS devices, and more recently in creating through silicon vias in 3D silicon structures for chip to chip interconnects. Precise control of the etch rate is extremely important in meeting the design characteristics of silicon devices produced using TDM plasma etch.

Virtual fabrication is a computerized technique to perform predictive, three dimensional modeling of semiconductor fabrication processes. Virtual fabrication allows engineers to test semiconductor process changes and process variability in minutes or hours, instead of the weeks or months required to test their designs using actual semiconductor wafers. SEMulator3D is a virtual fabrication solution that can model process variability under complex patterning schemes and process flows.

In this study, SEMulator3D was used to model the etch rate of silicon devices using TDM (or DRIE) etching processes. Predicted results are compared to actual published data, to determine if virtual fabrication can be used to minimize aspect ratio dependent etch variability

You might also be interested in:

- You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]

- You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]

- You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]

- You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]

Impact of EUV Resist Thickness on Local Critical Dimension Uniformities for <30 nm CD Via Patterning

Impact of EUV Resist Thickness on Local Critical Dimension Uniformities for <30 nm CD Via Patterning

You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]- You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]