Back-End-of-Line (BEOL) Virtual Patterning

May 26, 2013

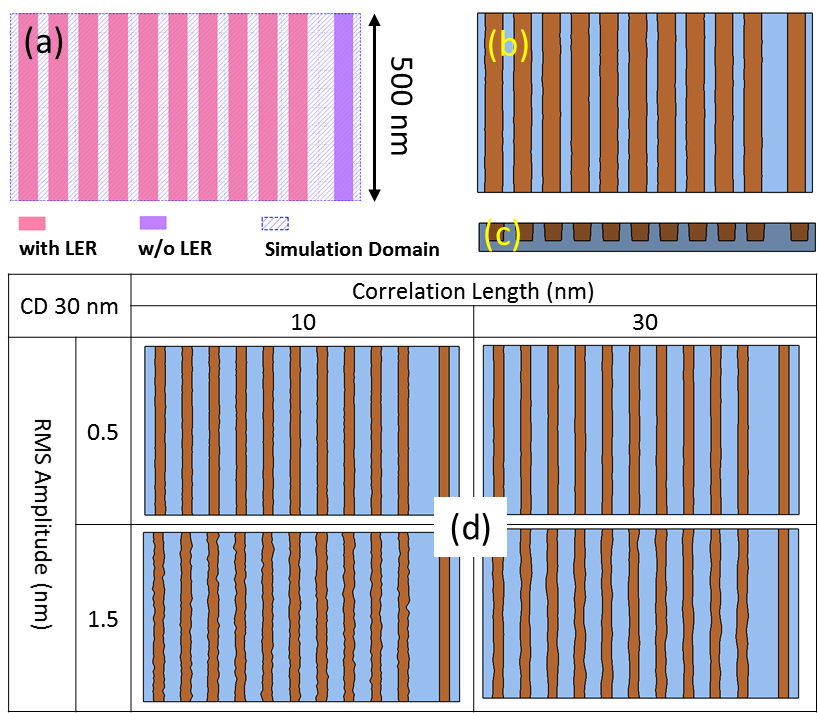

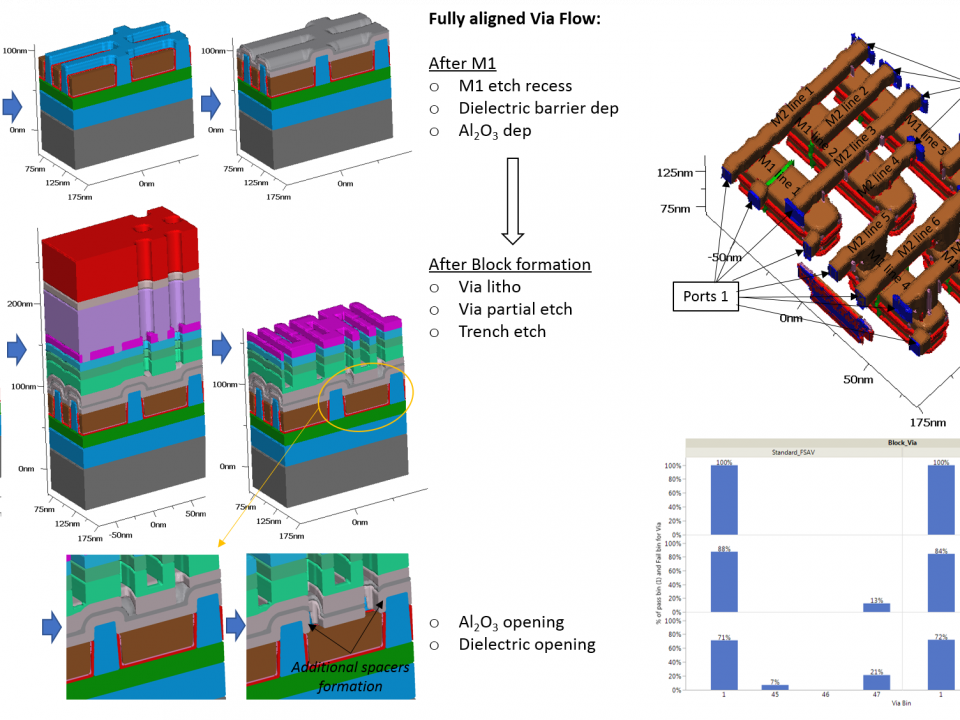

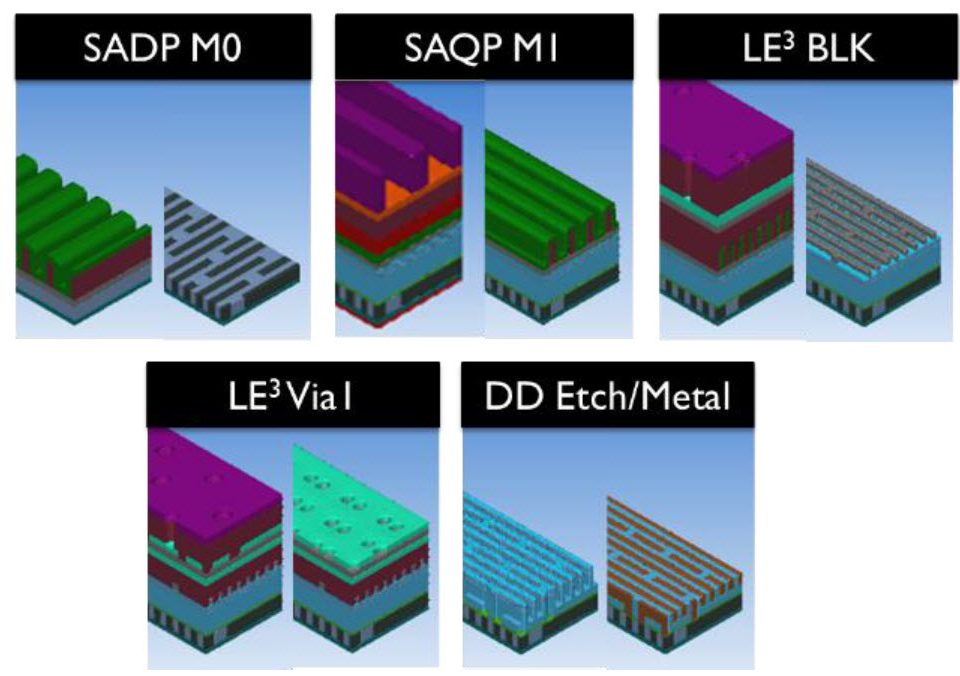

22nm Technology Yield Optimization Using Multivariate 3D Virtual Fabrication

September 9, 2013You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. If you do not have an account, we invite you to request an account.

Whitepaper: Back-End-of-Line (BEOL) Metallization

To download your free white paper, please fill out the form below:

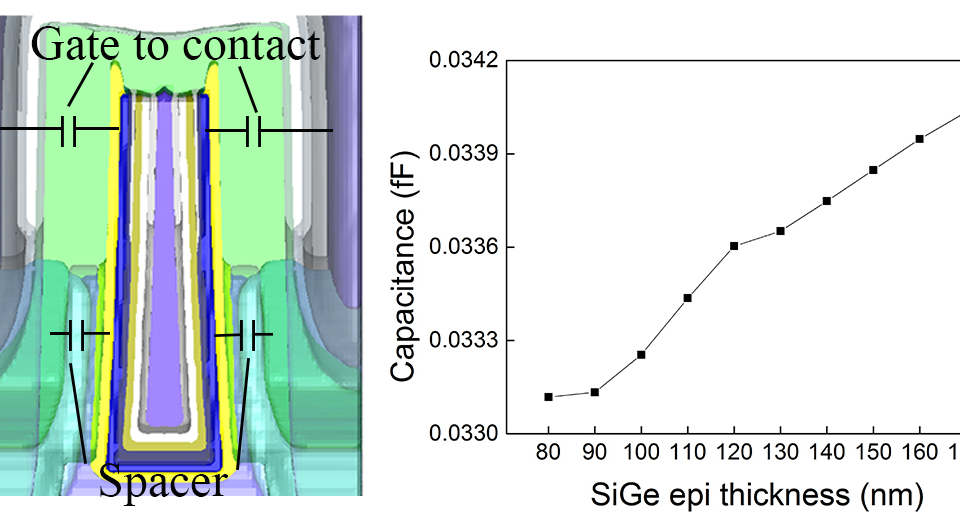

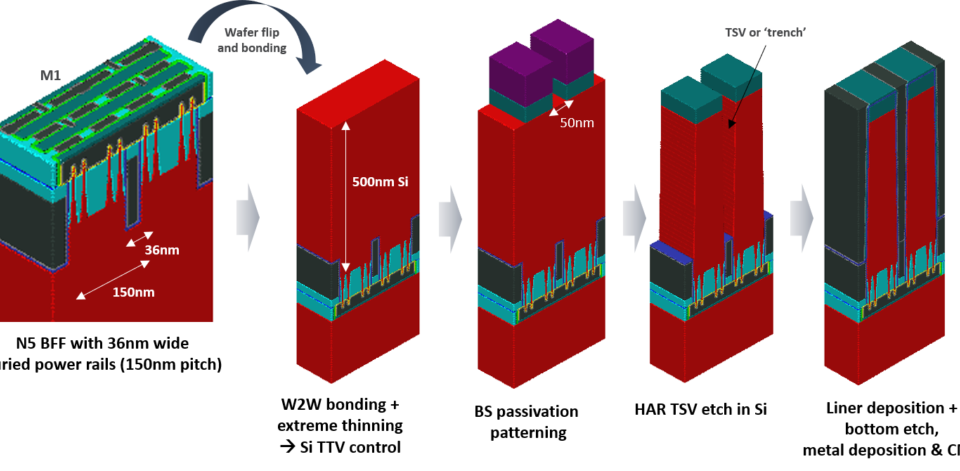

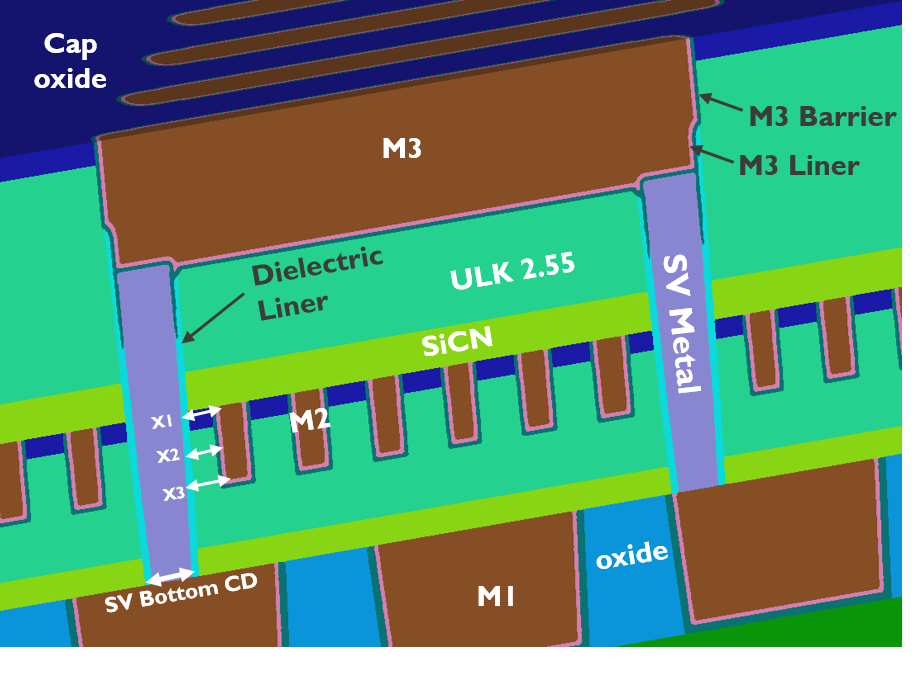

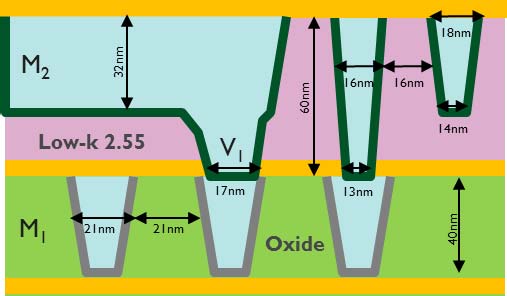

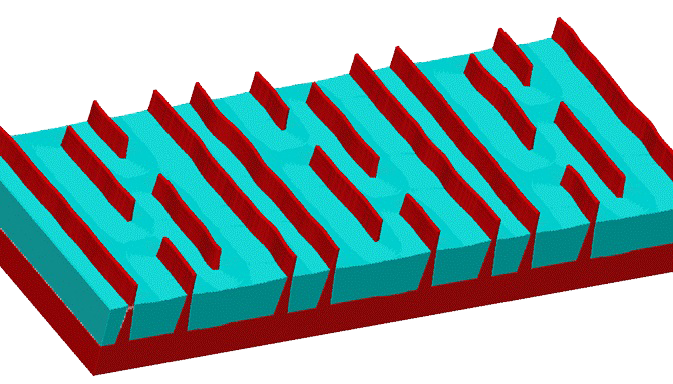

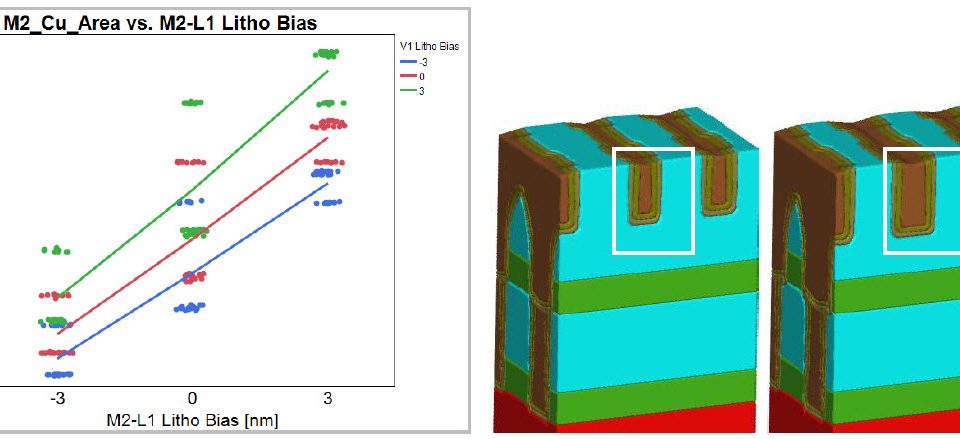

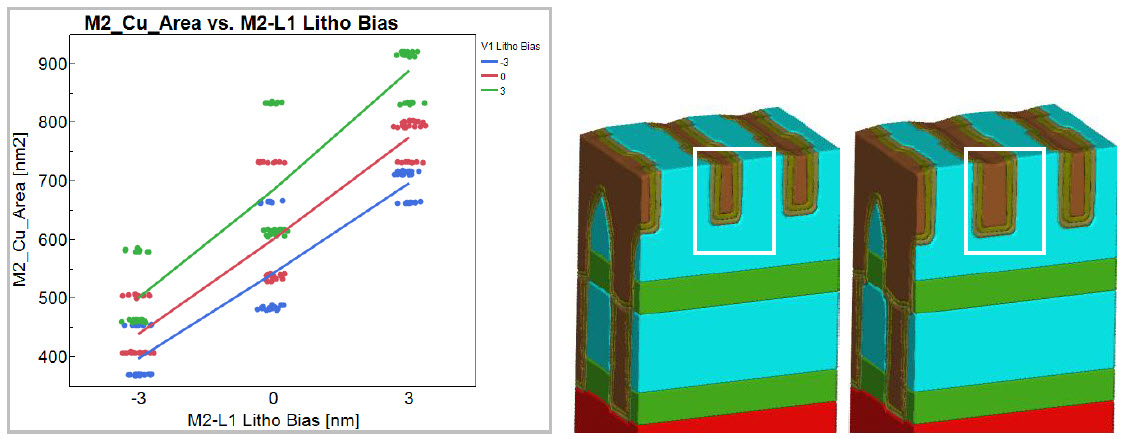

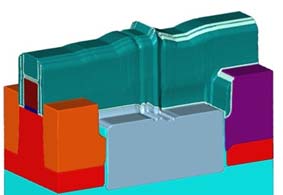

Physical Vapor Deposition (PVD) for Back-End-of-Line (BEOL) metallization has been pushed to the limits at the 16-nanometer (nm) technology node and beyond. Extending PVD for metal liner and barrier seed deposition is forcing the process into a narrow window that must be characterized prior to manufacturing introduction. Furthermore, understanding the liner dependency on the trench and via etch profile helps to identify process requirements for maximizing the process window. Destructive characterization required to properly define the process window poses severe analytical resource challenges. Virtual fabrication with a 3D process modeling platform can overcome this obstacle. A hypothetical M1-V1-M2 BEOL via chain is used to demonstrate the value of the capabilities of the SEMulator3D platform for predictive design-technology modeling, variation analysis and quantitative data extraction.

You might also be interested in:

- You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]

- You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]

- You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]

- You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]

- You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]

- You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]

- You must have an account on our Customer Portal to access this content. If you already have an account, please log in using the form below or to the right. […]